The Future

of Fusion

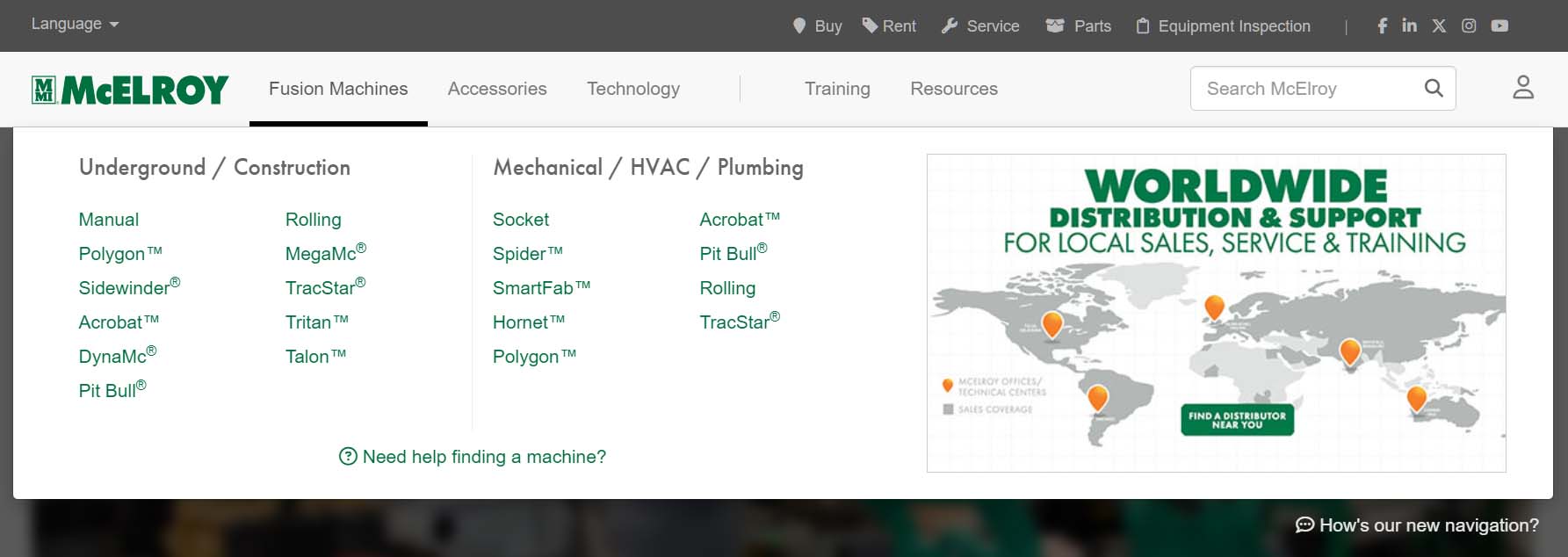

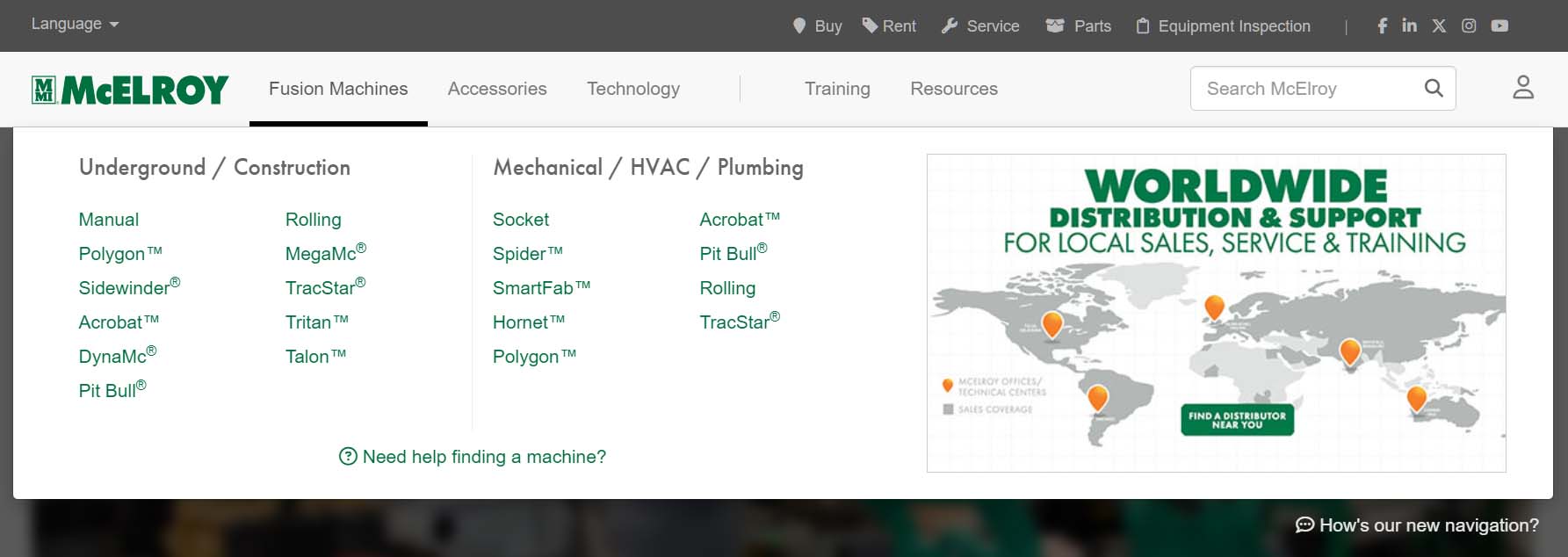

THE NEXT GENERATION OF TRACSTAR® MACHINES offers the industry a sophisticated, rugged and productive fusion machine. Numerous improvements have advanced the level of technology available while simultaneously hardening that technology to make the entire fusion experience more reliable. The TracStar iSeries features new emission-compliant engines, a CAN bus control system, along with numerous hydraulic, mechanical and electrical upgrades. Integrated, software-controlled machine options from manual to fully automatic improves operator consistency and adherence to standards.

Disable Hotspots

X

THE PERFECT AMOUNT OF CONTROL, EVERY FUSION

TRACSTAR® iSERIES MACHINES are powered by the new FusionGuide™ Control System. Integrated software guides the user through every step of the fusion process via an easy-to-use ruggedized tablet. After the operator prepares the pipe and enters all joint details, the enhanced guided workflow manages machine pressures, carriage movement, heater actions, shift sequence, and more to ensure standards compliance and a successful fusion.

INTEGRATED DATALOGGER® SOFTWARE automatically records every fusion joint — allowing for a comprehensive record of each fusion on the jobsite.

3 LEVELS OF MACHINE

CONTROL, from user-controlled to fully automatic, are available to aid in the operation.

Allows the operator to manually control carriage position and times during the fusion process

Software-controlled shift sequence and heating / fusion times with on-screen prompts

Fully automatic, software-controlled process