Welcome to our new navigation

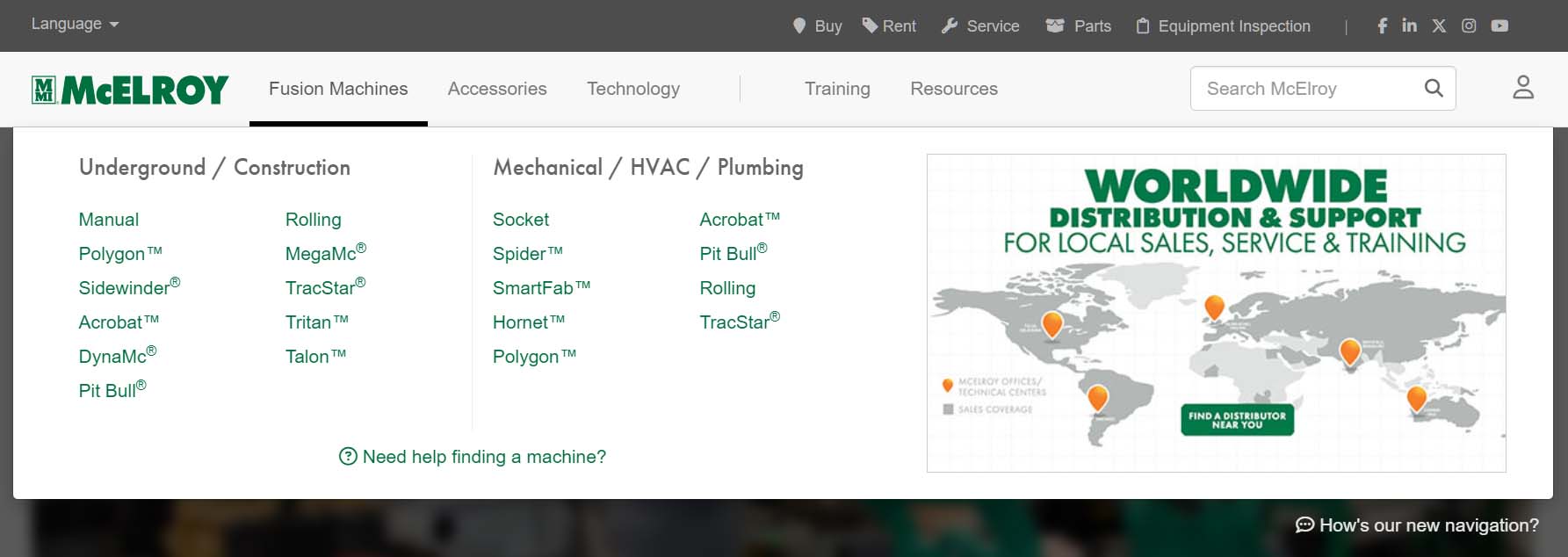

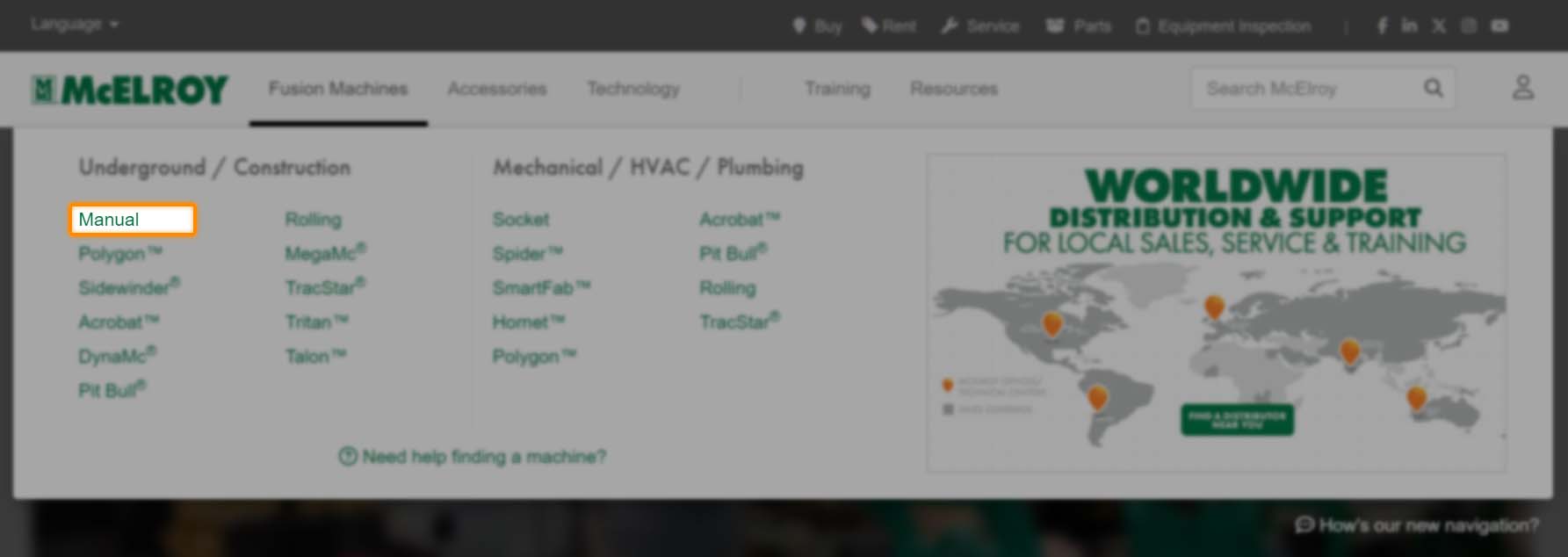

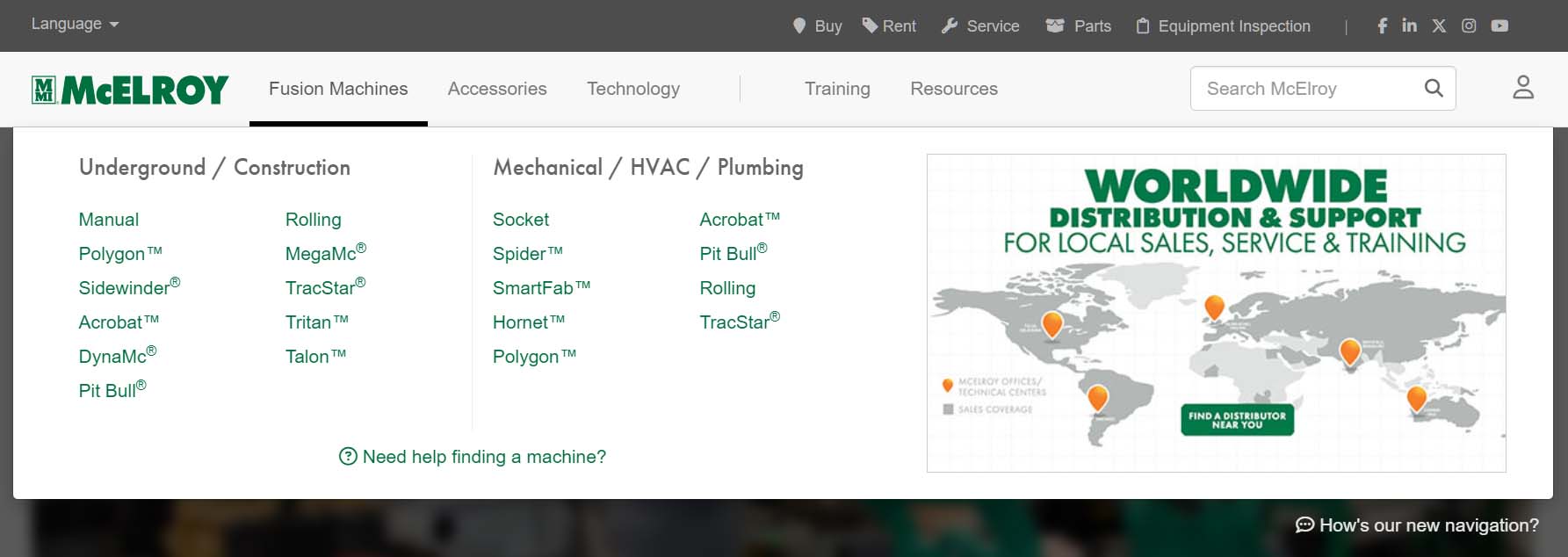

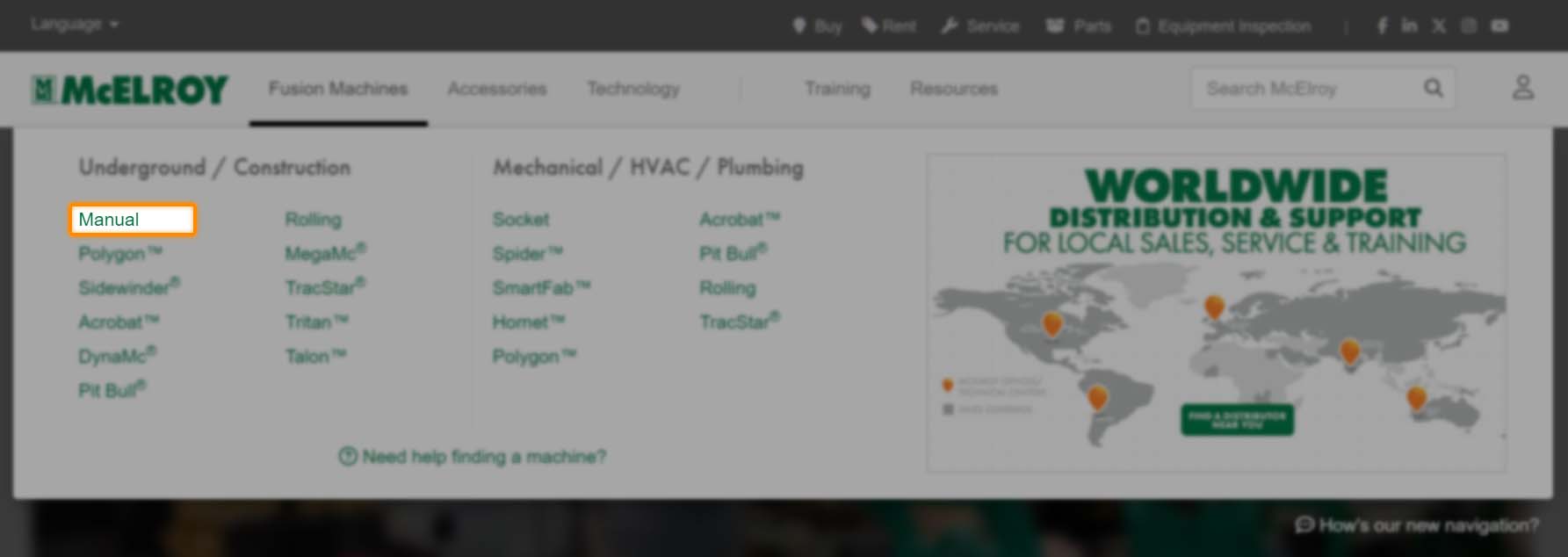

We've updated our menu to more quickly find the info you need. Select Fusion Machines, then the product family link under the appropriate industry.

We've updated our menu to more quickly find the info you need. Select Fusion Machines, then the product family link under the appropriate industry.